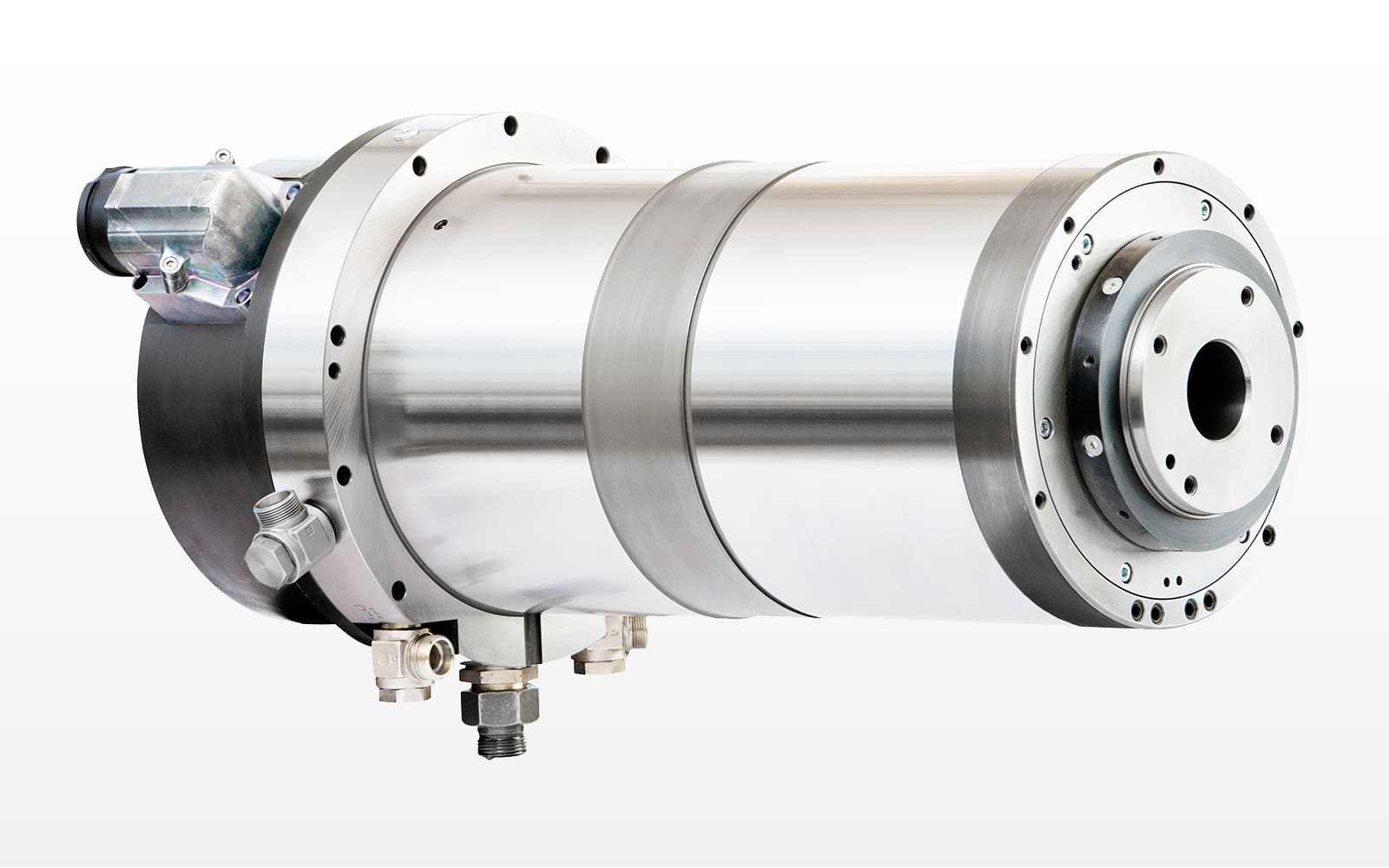

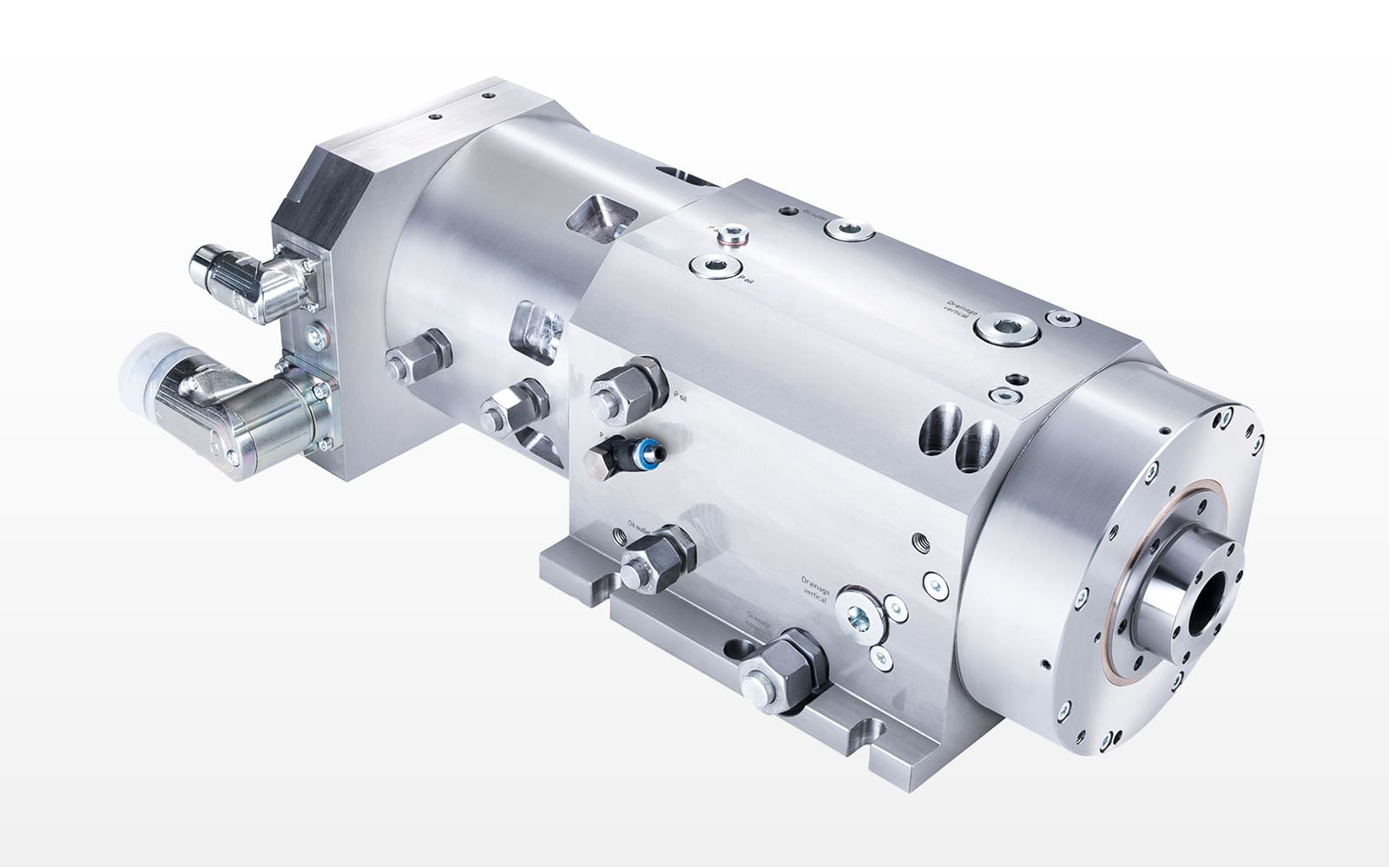

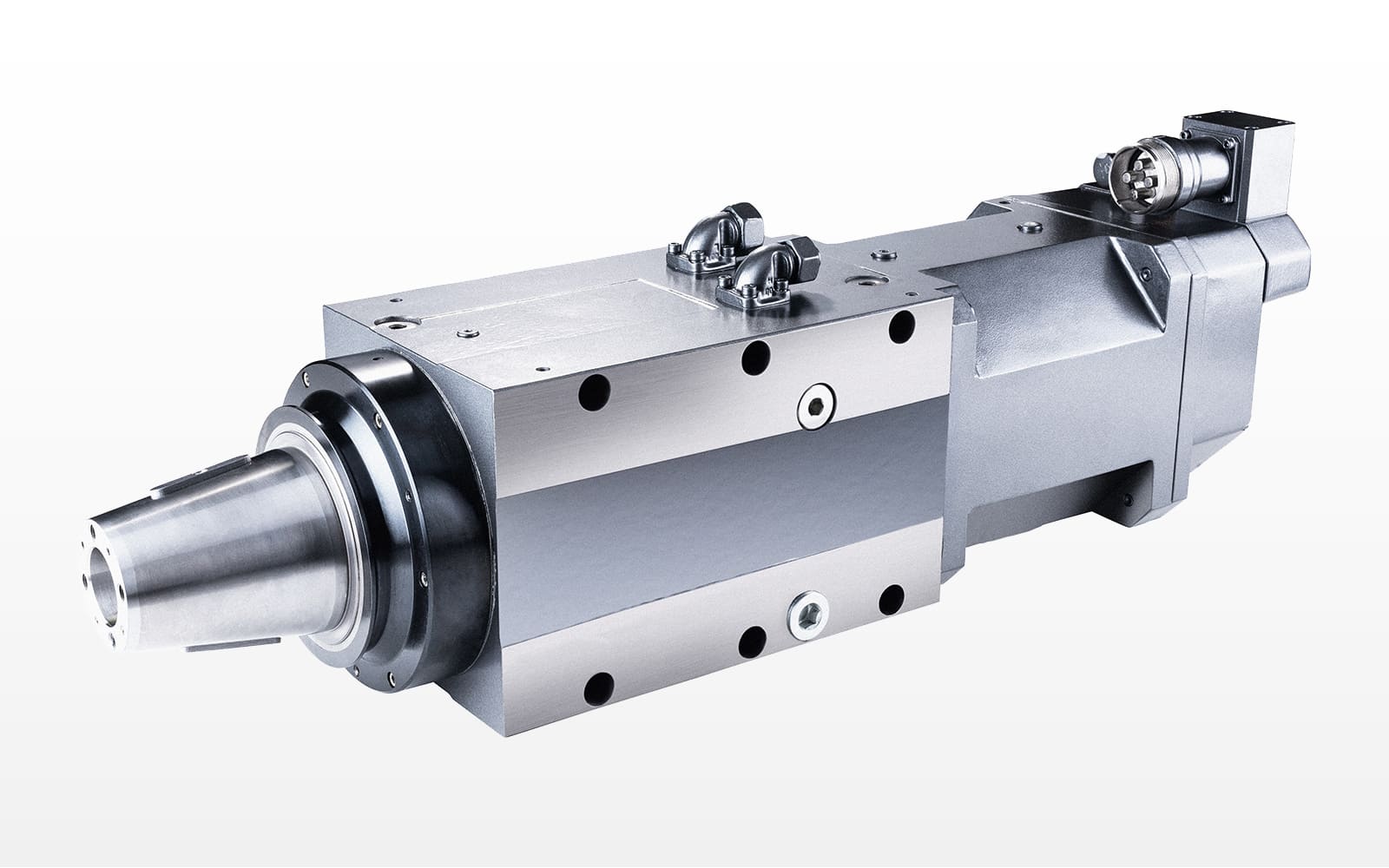

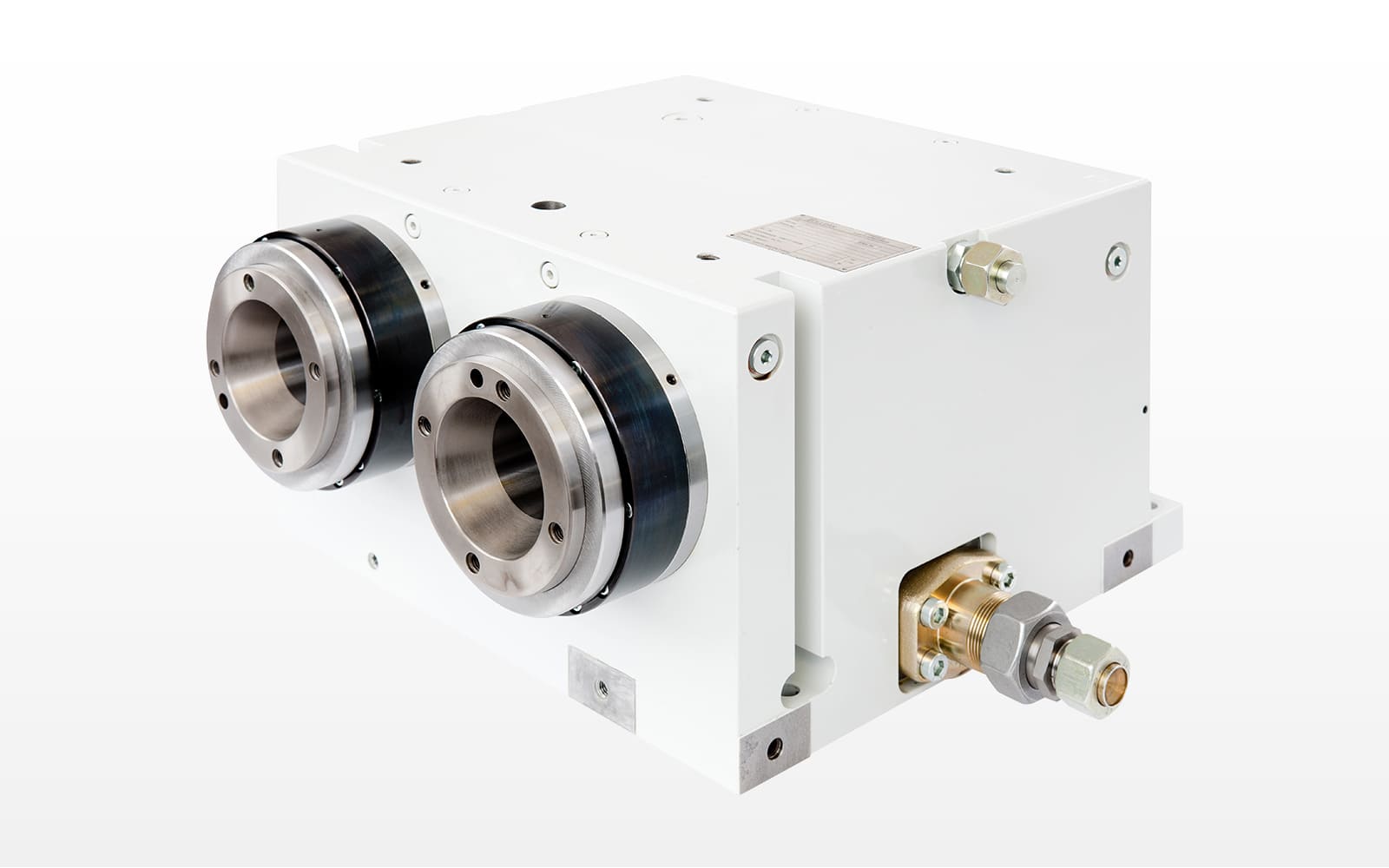

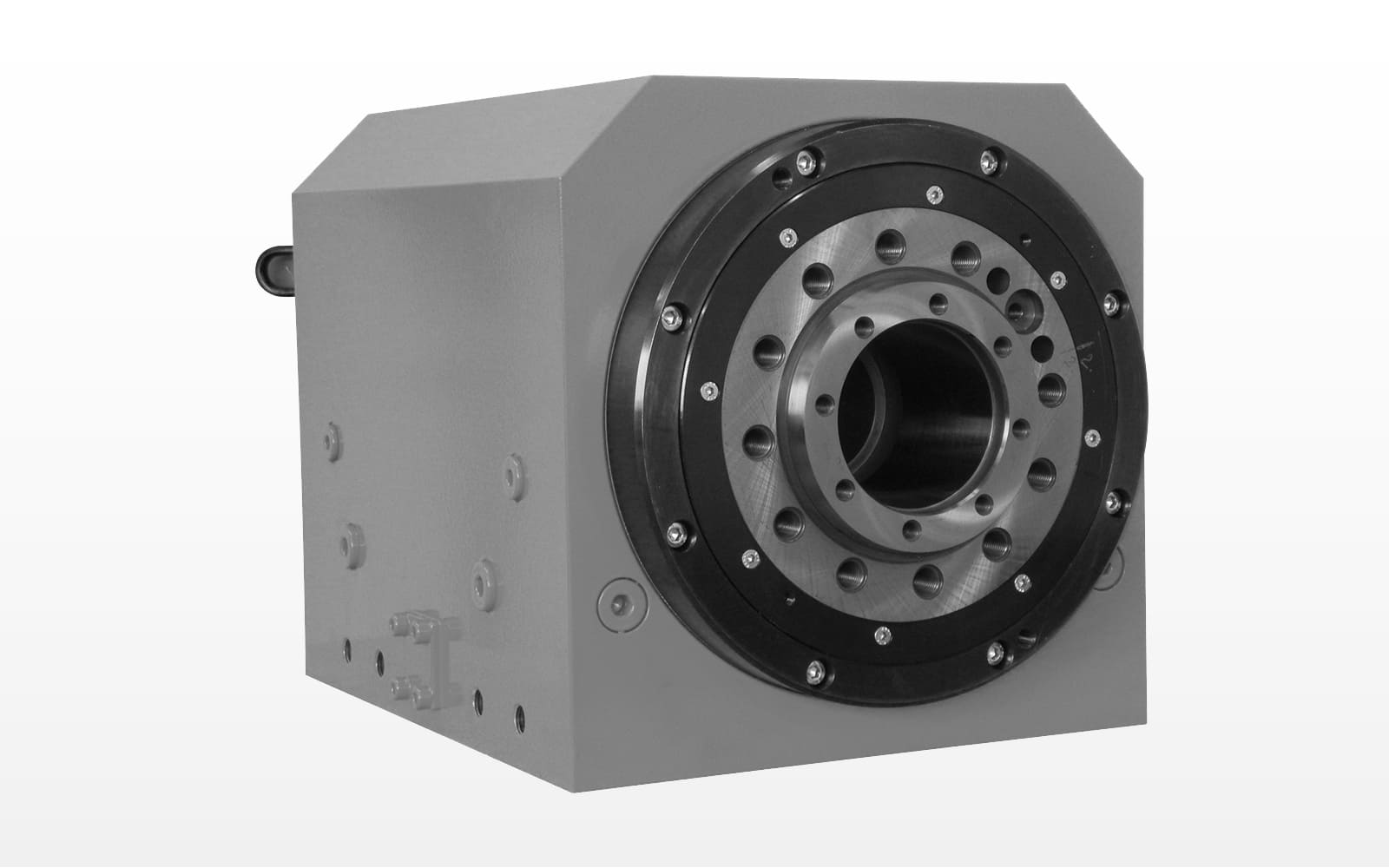

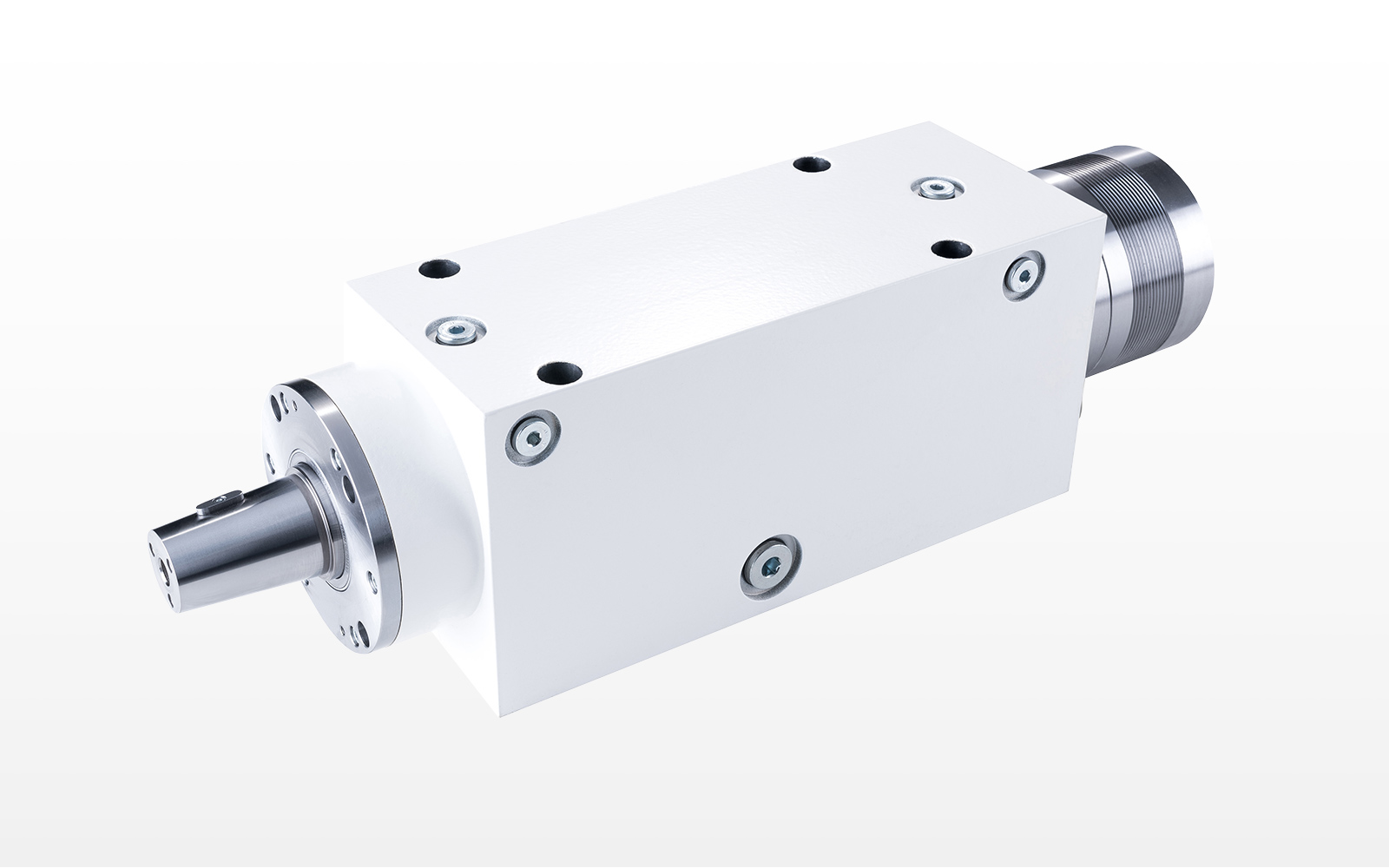

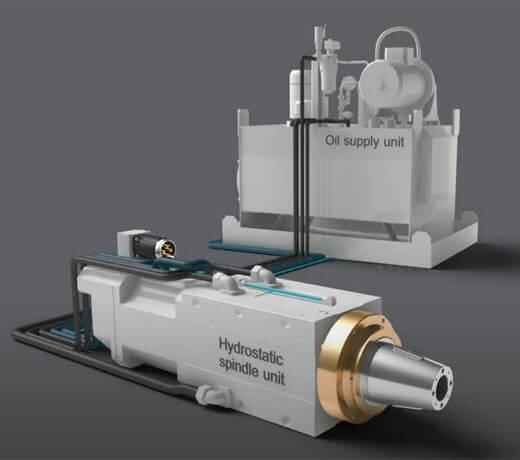

Hydrostatic spindles - Precise, wear-free, with a high running smoothness

The hydrostatic spindles from ZOLLERN impress with their very good concentricity and axial runout accuracy as well as the excellent damping, which makes it possible to achieve high surface qualities. The resulting heat is dissipated directly via the oil thanks to the constant oil circulation. This leads to a high thermal stability and consistently convincing technical properties.

The constant separation of bearing surfaces by a thin film of oil guarantees freedom from wear and therefore a calculative unlimited service life.

Features, advantages

Features

- The ZOLLERN bearing clearance compensator works without susceptible capillaries or controllers

- Dimensions according to customer requirements

- Optional delivery of complete hydraulic system and control

- Optional: Composite casting bearing with special emergency running properties

Advantages

- Calculative unlimited service life

- Concentricity and axial runout accuracy up to < 0.1 µm attainable

- Very good damping properties

- Thermally stable

- High level of running smoothness, no vibrations from rolling elements

Typical applications

- Turning machines

- Grinding machines

- Milling machines

- Fine boring machines

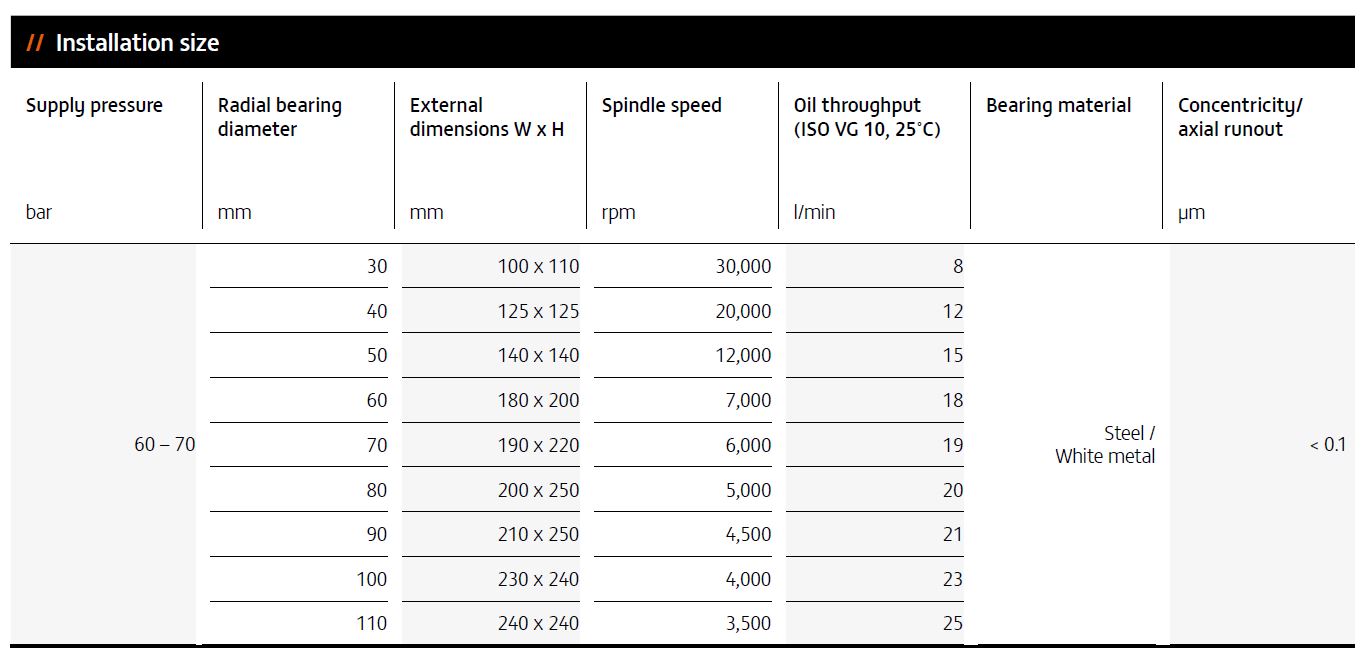

Technical Data

Hydrostatic spindle unit with ZOLLERN clearance compensator

The ZOLLERN clearance compensator ensures optimum pocket pressure in the spindle unit. It is integrated into the fully hydrostatic bearing part of the spindle and the optimum pocket pressure is automatically set within the manufacturing tolerances. The patented clearance compensator is a self-regulating system with fast control behaviour and high rigidity. It is used in spindles as well as in hydrostatic rotary tables and linear guides.